Control Measures

Essential steps to protect workers from isocyanate exposure – proper spray facilities, respiratory protection and clearance times.

Monitoring and Testing

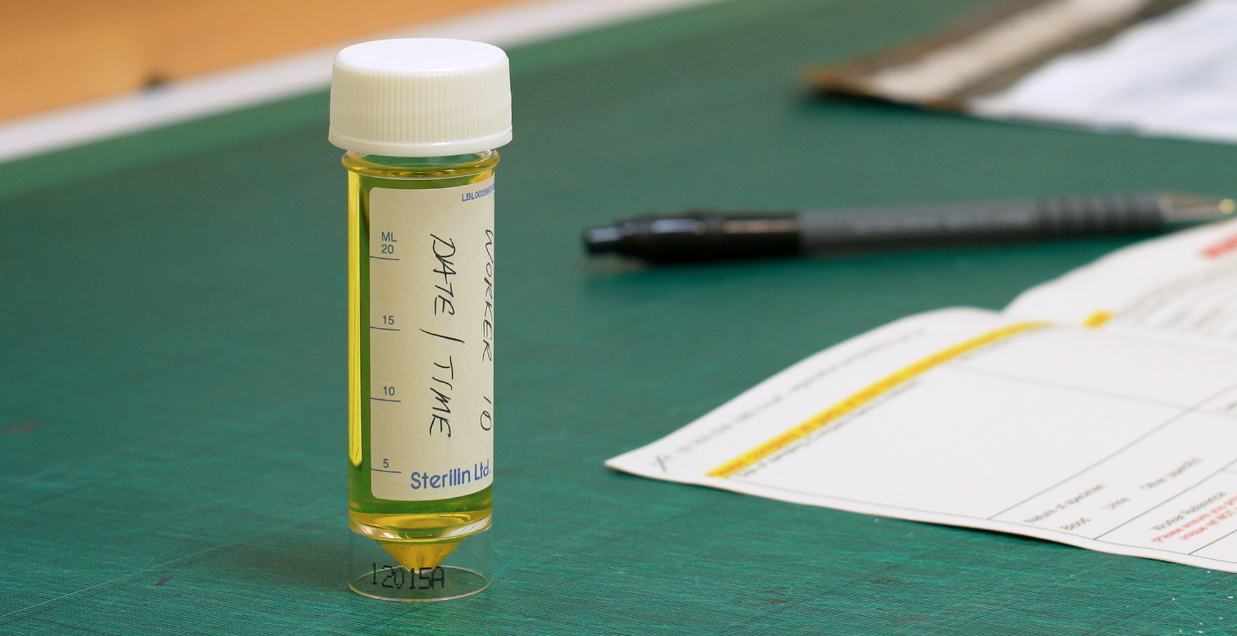

Guidance on biological monitoring and health surveillance requirements to check if your protection measures are working.

Resources

Downloads including control measures checklist, compliance guidance, videos and materials to share with your team.

Training & Legal Requirements

Find out about mandatory training requirements for workers using isocyanate paints and your legal duties under COSHH

Working with isocyanates

Isocyanates are one of the leading causes of occupational asthma in the UK. Every year, vehicle paint sprayers develop this life-changing condition. Once they have it even tiny amounts of isocyanate exposure can trigger an attack, which often forces them to leave the profession completely.

Two-pack (2k) paints, coatings and lacquers, are widely used for their durability and finish quality. However, when sprayed, these paints release invisible isocyanate-containing mist that spreads rapidly and can reach dangerous levels within minutes.

The Health and Safety Executive (HSE) is conducting inspections of motor vehicle repair businesses that use isocyanate-containing materials. These inspections focus on ensuring proper health and safety measures are in place. This guidance will help you protect your workers, comply with legal requirements, and prepare for inspections.

Three essential actions to stay safe:

(Tap or click to read more)

Always use proper spray facilities and correct respiratory protective equipment

You must use air-fed breathing apparatus – filtering respirators will not protect you.

Never allow 2-pack (2K) paints to be sprayed outside a proper spray booth or room.

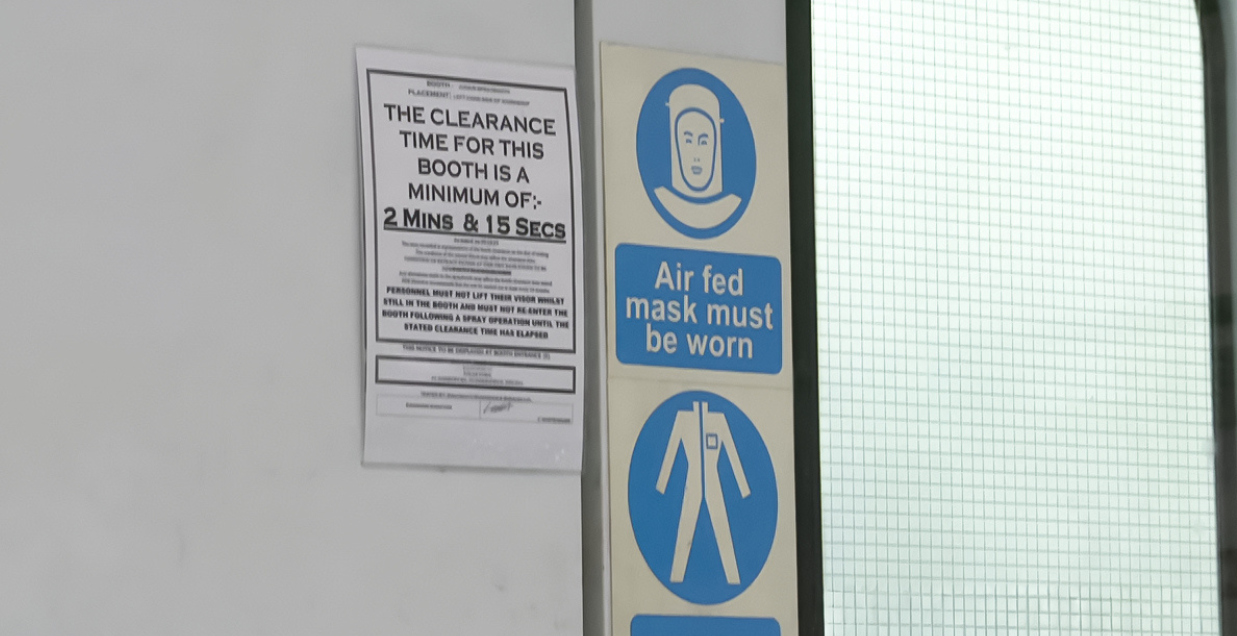

Respect clearance times – every time

Your spray booth needs time to clear invisible isocyanate paint mist.

Workers lifting visors too soon is a common mistake.

Monitor exposure levels regularly

Our legal duty under COSHH Regulation 10 requires exposure monitoring.

Biological monitoring through urine testing is HSE and industry’s recommended method.