Isocyanates legal requirements

Your legal duties and mandatory training requirements for using isocyanate paints

Protecting your workers from isocyanate exposure is a legal requirement. Failure to comply can result in serious health consequences for your employees and significant penalties for your business.

Legislation under COSHH

The Control of Substances Hazardous to Health (COSHH) Regulations 2002 set out specific requirements when using isocyanates:

(Tap or click to read more)

Risk assessment

COSHH Regulation 6 states you must carry out a suitable and sufficient risk assessment of health risks. If you employ 5 or more people, you must record this assessment and review it regularly.

Prevention and control

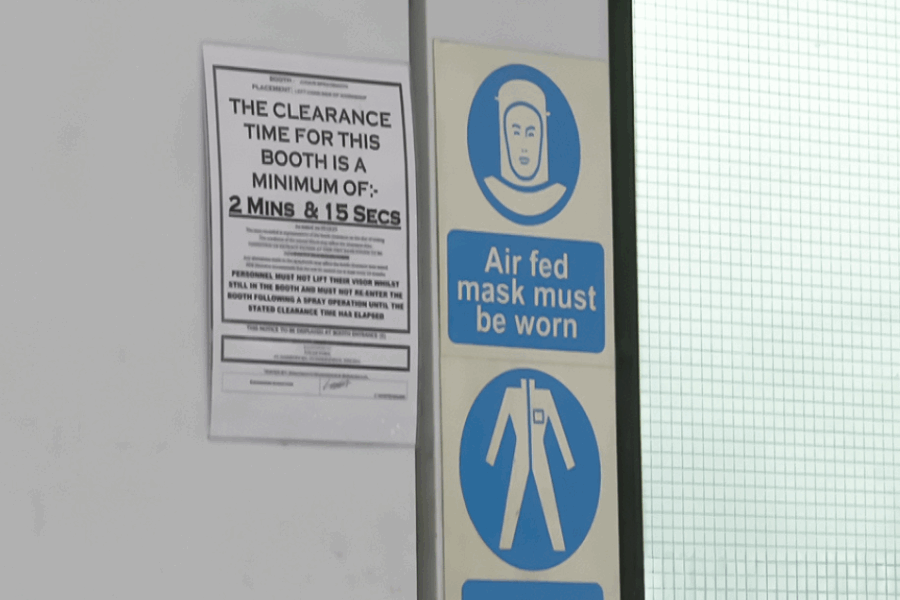

COSHH Regulation 7 states must prevent exposure where reasonably practicable or adequately control it. This means using proper spray booths with extraction systems and providing appropriate respiratory protective equipment.

Maintenance and testing

COSHH Regulation 9 states control measures must be maintained in efficient working order. Spray booth extraction systems require thorough examination and testing every 14 months. Respiratory protective equipment must be regularly tested.

Monitoring Exposure

COSHH Regulation 10 states where your risk assessment identifies it as necessary, you must monitor workers’ exposure. Biological monitoring through urine testing is the recommended method for isocyanates.

Health Surveillance

COSHH Regulation 11 states you must arrange appropriate health surveillance for workers exposed to isocyanates using competent occupational health professionals.

Training

COSHH Regulation 12 states you must provide robust training appropriate to the hazard. Workers must understand the risks and control measures before they start work with isocyanates.

Read the full COSHH Code of Practice and guidance.

Mandatory training requirements

UK REACH regulations restrict the use of isocyanate-containing materials. You have a legal duty to ensure all workers complete approved training before using these materials.

Training must cover

- Health hazards including occupational asthma risk

- Correct use of respiratory protective equipment (RPE)

- Safe working procedures and clearance times

- Emergency procedures and first aid

- Storage and handling requirements

Training frequency: At least every 5 years or when work methods change significantly.

Records: Keep training records to demonstrate compliance during HSE inspections.

Check the UK REACH list of restrictions for training providers and requirements.

Other legal requirements

Legislation

Key requirement

| Ensure worker health, safety and welfare so far as reasonably practicable |

| Provide competent health and safety advice and management systems |

| Maintain equipment in efficient working order |

| Store flammable paints safely away from ignition sources |

Enforcement

HSE inspectors have the power to:

- Issue improvement notices requiring specific changes within set timeframes

- Issue prohibition notices to stop dangerous work immediately

- Prosecute, leading to unlimited fines and potential imprisonment

Recent prosecutions have resulted in significant financial penalties for companies failing to protect workers from isocyanate exposure.

Remember: Isocyanate exposure can cause life changing occupational asthma that can end careers. Protecting your workers protects your business and preserves the skilled workforce the industry depends on.